Boost Productivity: Just How Updating Undercarriage Parts Can Improve Efficiency

Boost Productivity: Just How Updating Undercarriage Parts Can Improve Efficiency

Blog Article

Maximize Performance With Durable Undercarriage Components

In the realm of hefty equipment and equipment, the role of undercarriage parts is paramount in making sure optimum efficiency and longevity. The efficiency and effectiveness of these elements can significantly affect the general procedure of equipment, making the choice of sturdy undercarriage components a crucial decision for drivers and managers alike.

Advantages of Using Resilient Undercarriage Components

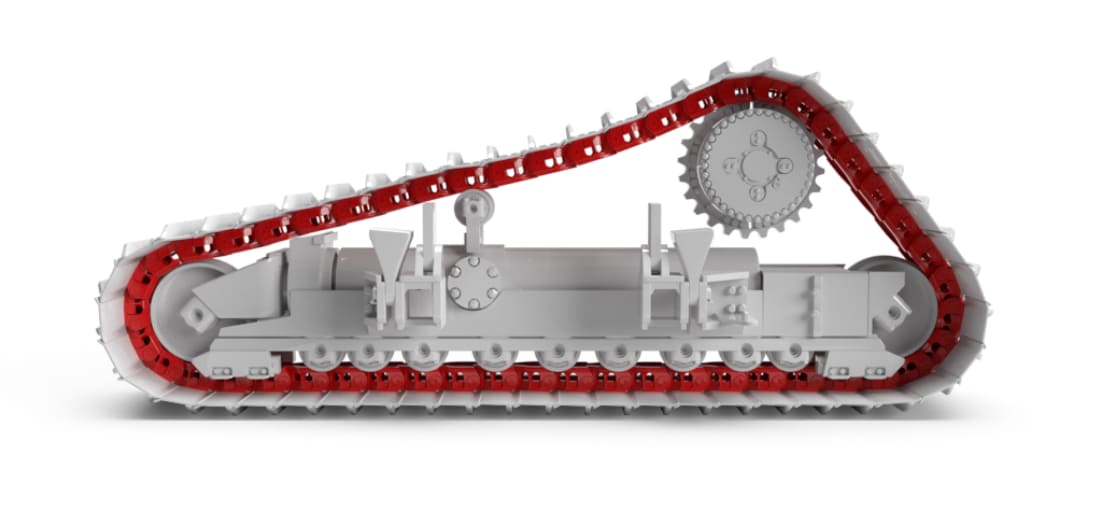

Utilizing long lasting undercarriage components not just improves the longevity of hefty equipment yet additionally decreases upkeep costs substantially. By buying high-grade undercarriage parts, such as tracks, rollers, idlers, and gears, devices operators can experience enhanced uptime and improved total efficiency.

Moreover, the long life of heavy machinery is straight connected to the top quality of its undercarriage parts. Resilient elements can stand up to the roughness of requiring applications, ensuring that the equipment remains operational for extensive durations. Because of this, drivers can stay clear of costly downtime and upkeep expenditures, eventually taking full advantage of the return on financial investment for their machinery.

Factors Impacting Undercarriage Sturdiness

The durability of undercarriage parts in hefty equipment is affected by various important factors that directly impact efficiency and long life. Premium materials, such as hardened steel, are important for holding up against the extreme problems and hefty tons that undercarriage components are subjected to - undercarriage parts.

Moreover, ecological elements can have a substantial impact on the durability of undercarriage components. Direct exposure to abrasive materials, severe temperatures, and harsh working problems can increase damage on undercarriage parts. Consequently, selecting undercarriage parts that are especially created to hold up against these ecological challenges is vital for guaranteeing longevity.

Additionally, the layout and engineering of undercarriage components have a direct influence on their toughness. Components that are created to disperse tons equally, lower rubbing, and decrease tension concentrations are most likely to have a longer life-span - undercarriage parts. By taking into consideration these vital aspects, devices drivers can make best use of the toughness and efficiency of their undercarriage parts

Upkeep Tips for Prolonging Undercarriage Life

Executing routine upkeep regimens is important for extending the lifespan of undercarriage parts in heavy equipment. Furthermore, guarantee that the undercarriage is effectively oiled according to manufacturer standards to minimize rubbing and prevent early wear.

Another important maintenance suggestion is to maintain the undercarriage clean from dirt, rocks, and debris. Build-up in the undercarriage can accelerate wear and rust, leading to pricey repair work. Washing the undercarriage after procedure in rough problems is suggested to stop these problems.

Last but not least, tracking and recording upkeep activities can help in producing a proactive maintenance timetable. Keeping thorough records of examinations, substitutes, and repair work can offer useful understandings into the undercarriage's problem and efficiency gradually, assisting in anticipating and avoiding possible failures. By complying with these upkeep ideas carefully, drivers can dramatically raise the toughness and efficiency of undercarriage components in heavy machinery.

Selecting the Right Undercarriage Components

Picking proper go now undercarriage parts is important for making best use of the effectiveness and long life of hefty machinery. When it pertains to picking the best undercarriage elements, there are a number of factors to think about. One essential element is understanding the specific requirements of the machine and the atmosphere in which it will operate. Various applications might call for various sorts of undercarriage elements, such as tracks, gears, rollers, and idlers. It is necessary to select components that are made to hold up against the particular conditions the equipment will encounter, whether it be harsh surface, rough products, or severe temperatures.

Opting for trusted brand names recognized for creating high-performance and resilient undercarriage parts can considerably influence the total performance and longevity of the machinery. By carefully selecting the best undercarriage parts, devices owners can boost productivity, decrease downtime, and expand the life-span of their heavy equipment.

Study: Boosted Performance With Resilient Components

Integrating long lasting undercarriage components has actually demonstrated significant enhancements in machinery performance. One situation research study involved a construction business that updated its excavator's undercarriage components to extra sturdy choices.

In one more circumstances, a mining procedure changed the undercarriage components of its excavator with high-grade, resilient alternatives. This switch resulted in an impressive improvement in the excavator's ability to move and general efficiency. The maker could browse challenging terrains a lot more successfully, resulting in boosted operational performance and reduced fuel intake.

Furthermore, a logging business spent in long lasting undercarriage parts for its forestry equipment. These case research studies underscore the substantial benefits of using sturdy undercarriage parts in maximizing machinery performance and longevity.

Conclusion

To conclude, utilizing long lasting undercarriage components can dramatically boost efficiency and durability of heavy machinery. Variables such as appropriate maintenance and picking the ideal elements play a vital role in making best use of undercarriage toughness. By implementing these approaches, businesses can lower downtime, increase efficiency, and eventually save on operational prices. Study have Check Out Your URL revealed that purchasing durable undercarriage check my source components can cause enhanced overall efficiency and efficiency in different sectors.

The effectiveness and effectiveness of these elements can substantially affect the general procedure of equipment, making the choice of durable undercarriage parts an essential decision for managers and operators alike.Integrating resilient undercarriage parts has actually demonstrated substantial enhancements in equipment efficiency. These situation research studies emphasize the concrete benefits of using sturdy undercarriage parts in optimizing equipment performance and durability.

In final thought, making use of long lasting undercarriage parts can dramatically enhance performance and longevity of heavy equipment (undercarriage parts). Case research studies have actually shown that investing in resilient undercarriage parts can lead to improved general efficiency and productivity in numerous industries

Report this page